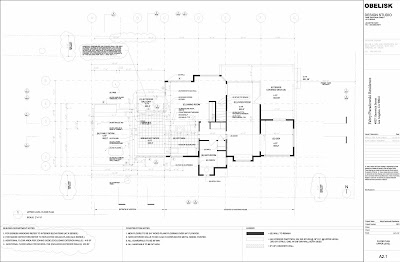

This week the crew layed out the first floor and framed most of the walls.

| Framing notes on the plywood...this is where a window is going. |

| sketch of a window |

| The orange lines are the chalk dust The other colors are showing where the wood studs and columns should be framed. |

sides and use the framing notes to attach

wood studs to the top and bottom plates.

they lift them into place and nail them.

| Holding the walls in place while they are nailed. |

| The second wall gets lifted into place. |

After the second day all but one of the first floor walls are framed...below is a view from the corner window of the Master Bedroom. The stud in the corner is bracing the walls until the beams are framed above. Eventually the window that goes in here has no corner mullion so that the view will be clear.

Bea and Ella in the Master Bedroom...

| View from Bedroom to Bathroom |

| View from new lower hallway to side yard - after the framing is done there is going to be a lot of grading to do and several garden walls to make to navigate the slopes of the back yard. |